Flexjoint Expansion Joint System

Back to Home

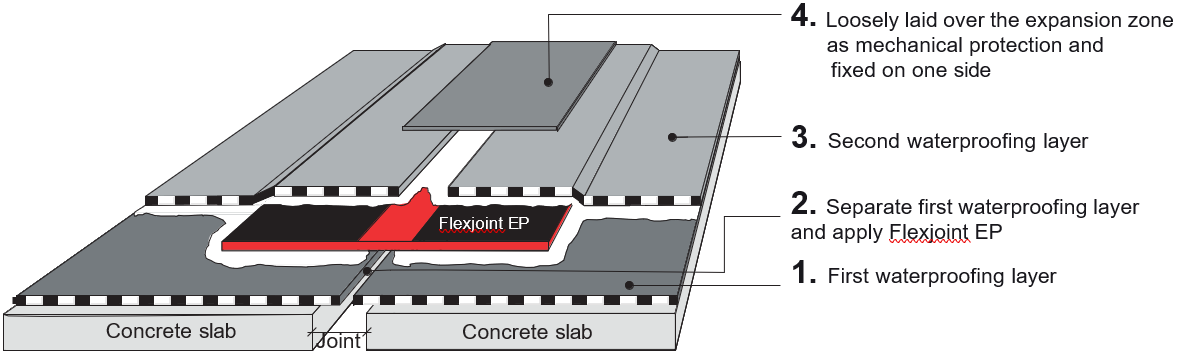

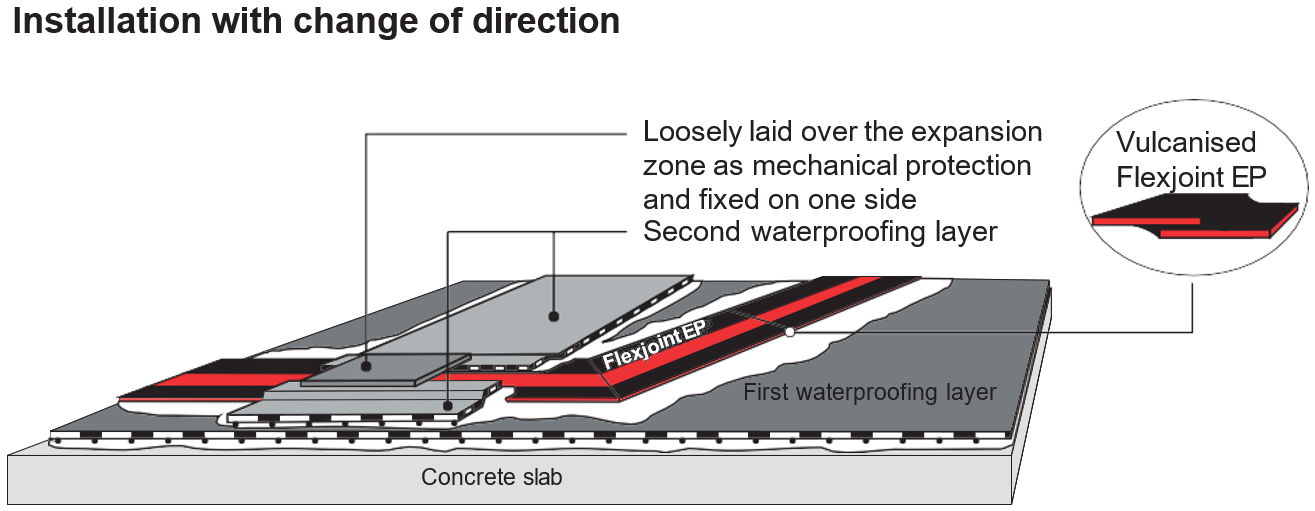

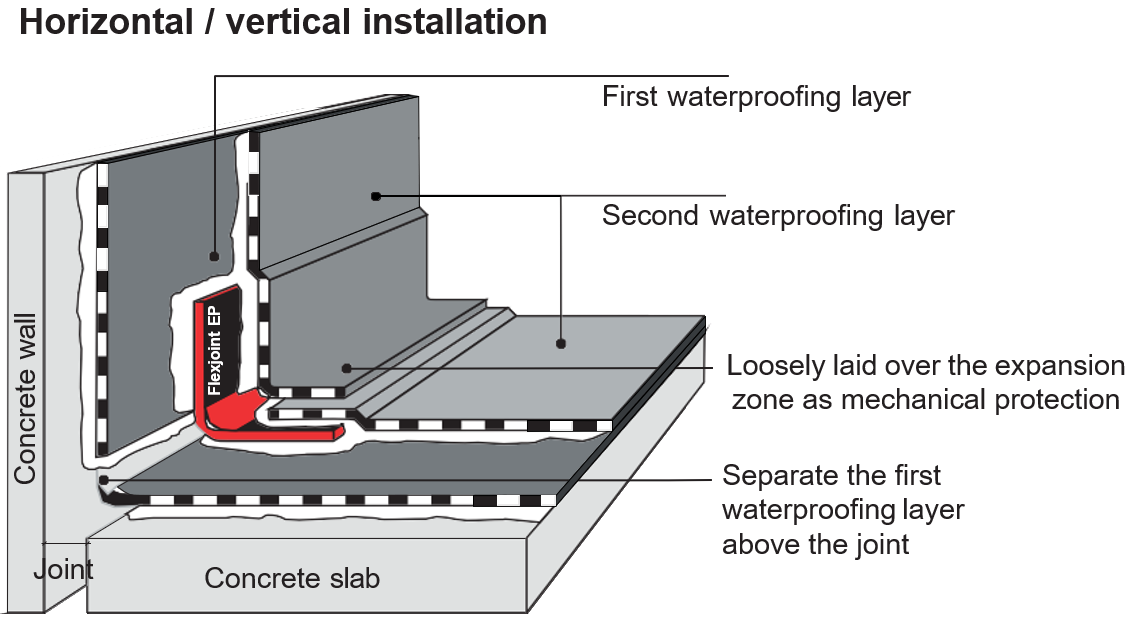

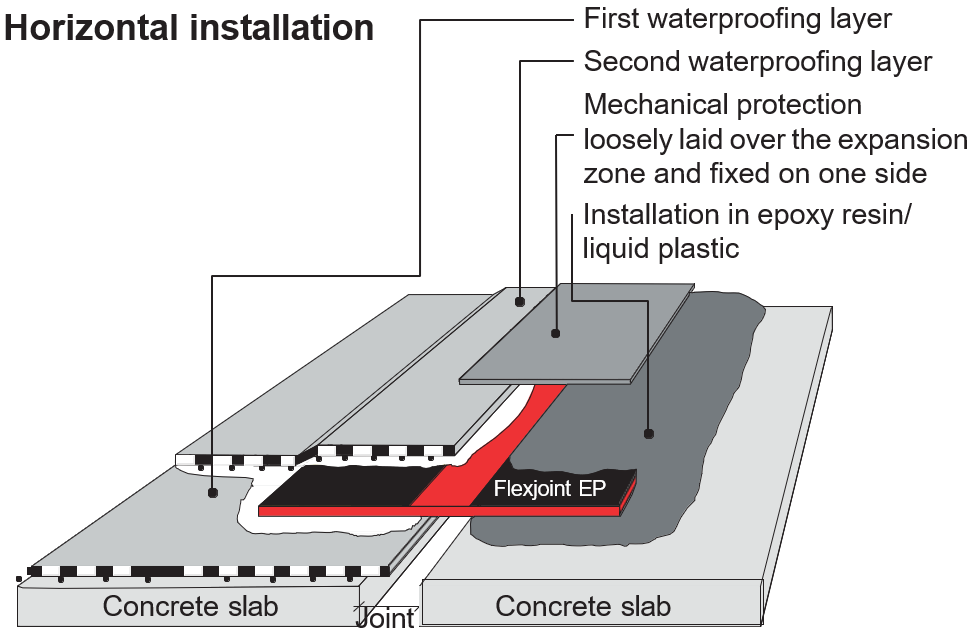

Flexjoint expansion joint strips are made of EPDM rubber and are the perfect solution for sealing roofs and buildings.

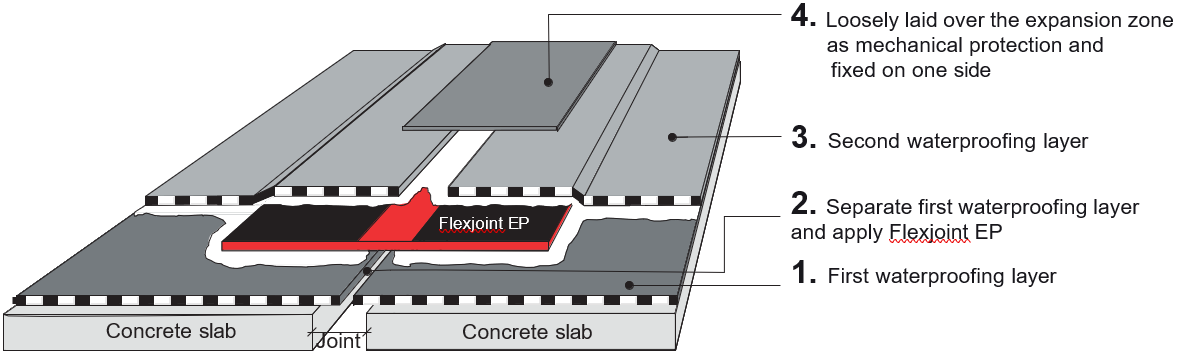

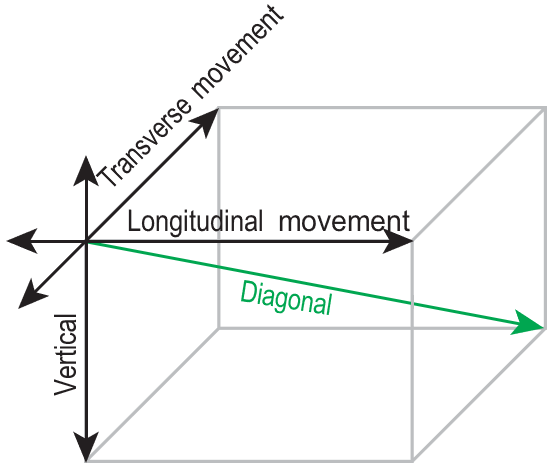

- highly elastic, simultaneously absorbing 3D movements

- durable without plasticizer

- a permanent bond without weak points thanks to vulcanization technology

- low installation height

- the flame retardant carbon nonwoven material adheres excellently without prior treatment

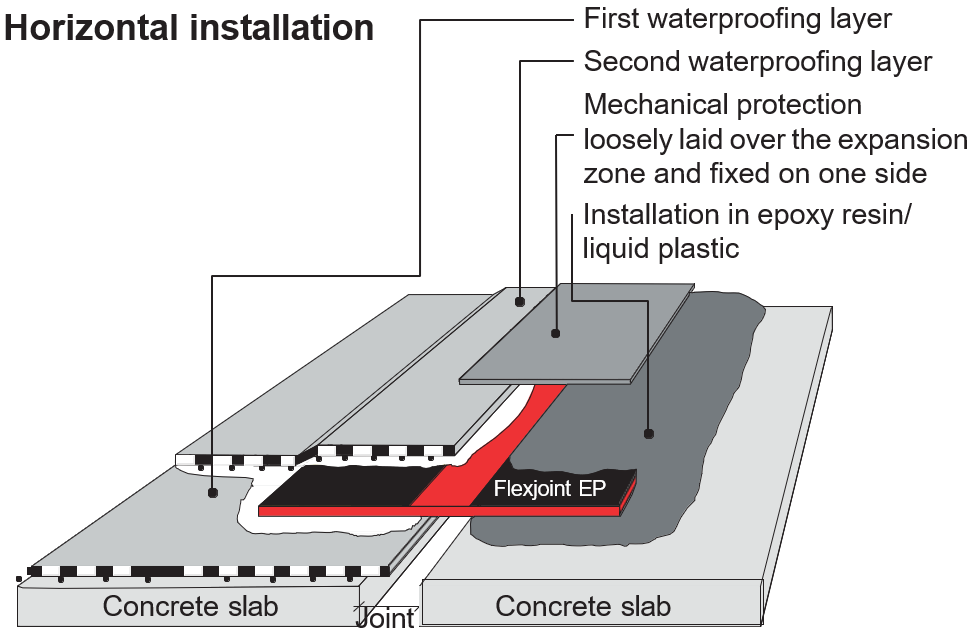

- Perfect for bitumen, liquid plastic and epoxy glue

|

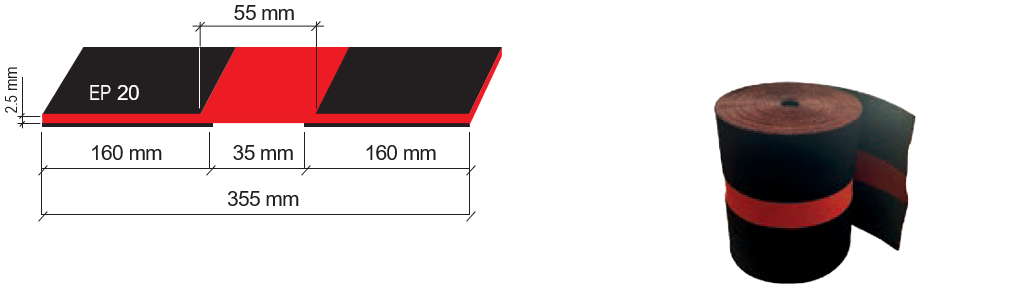

Flexjoint EP20 +/- 20 mm expandable in longitudinal/transverse/vertical direction diagonally up to +/- 35 mm |

|

|

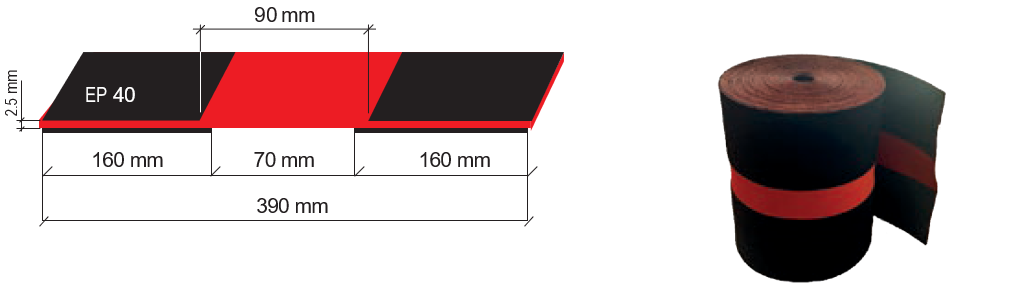

Flexjoint EP40 +/- 40 mm expandable in longitudinal/transverse/vertical direction diagonally up to +/- 70 mm |

|

|

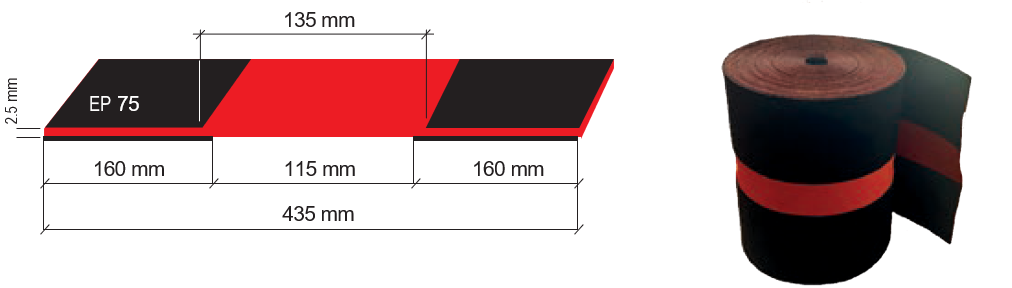

Flexjoint EP75 +/- 75 mm expandable in longitudinal/transverse/vertical direction diagonally up to +/- 130 mm |

|

|

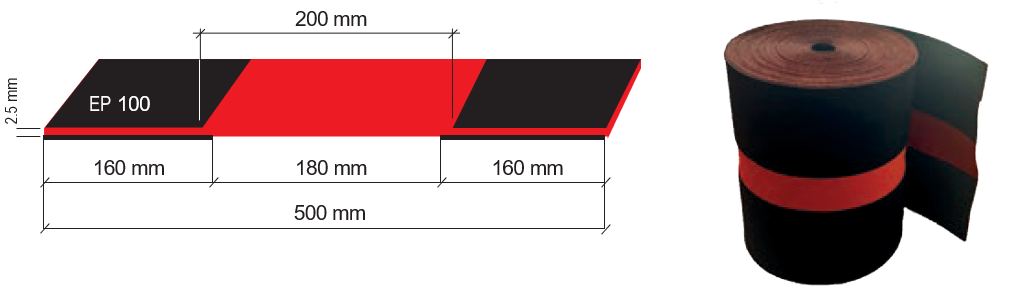

Flexjoint EP100 +/- 100mm expandable in longitudinal/transverse/vertical direction diagonally up to +/- 175 mm |

|

|

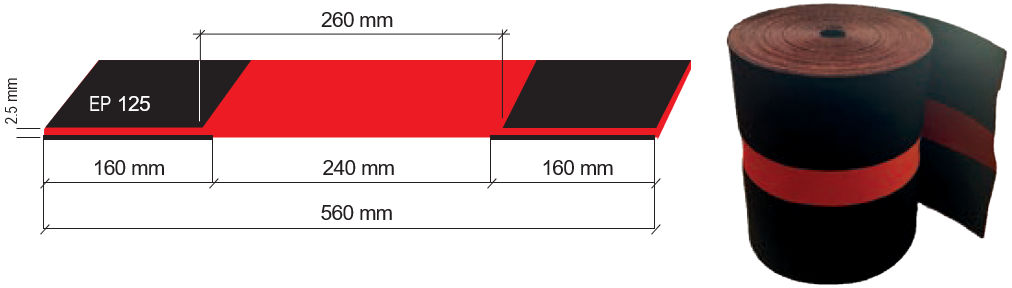

Flexjoint EP125 +/- 125mm expandable in longitudinal/transverse/vertical direction diagonally up to +/- 215 mm |

|

The EPDM material also has good general resistance to chemicals.

Resistance to non-polar plasticisers and solvents (e.g. mineral oils, petrol, fuels and aromatics such as toluene) is low. Constant contact with these media should be avoided.

Short-term contact during the installation phase with the open flame does not cause any impairment of the material properties.

| Test | Unit | Test Standard | Test value |

|---|---|---|---|

| Hardness | Shore A | DIN 53505 | 40 ± 5 |

| Tensile strength | N / mm² | DIN 53504 | > 10 |

| Elongation at break | % | DIN 53504 | > 700 |

| Compression set (at 23°C and 70°C) respectively | % | DIN ISO 815-1 | 20% and 44 % |

| Resistance to ozone cracking | Crack level | DIN 53509-1 | Crack level 0 |

| Water vapour diffusion resistance | µ | DIN EN ISO 12572 | 83,000 µ |

| Fire behaviour | DIN EN 13501-1 | Class E | |

| Alkali resistance (storage in lime water) | DIN EN 1847 | average > 5% | |

| Folding at low temperatures - 40°C | DIN EN 495-5 | No cracks | |

| Resistance to ageing (UV, temp. / water) | DIN EN 12974 | No cracks |

excellent properties against ozone concentrations excellent properties against ozone concentrations |

very good long-term exposure heat resistance (up to +120˚C) very good long-term exposure heat resistance (up to +120˚C) |

very good flexibility at low temperatures (down to - 40˚C) very good flexibility at low temperatures (down to - 40˚C) |

excellent properties against UV rays excellent properties against UV rays |

excellent against water and water vapour excellent against water and water vapour |

very good against alkalis, diluted acids and salt solutions very good against alkalis, diluted acids and salt solutions |

very good resistance to polar solvents such as alcohol and ketones very good resistance to polar solvents such as alcohol and ketones |